Troubleshooting Usual Issues with Your Galvanometer Scanner: Advice

Troubleshooting Usual Issues with Your Galvanometer Scanner: Advice

Blog Article

Exactly How a Galvanometer Scanner Improves Performance in Laser Scanning Technologies

The combination of galvanometer scanners in laser scanning innovations represents a crucial development in accuracy engineering. By helping with quick and precise changes of laser light beam direction, these devices considerably enhance functional performance throughout numerous applications, from medical imaging to commercial engraving. The underlying electromagnetic systems, combined with innovative comments systems, guarantee real-time control and improved accuracy. Nonetheless, as industries progressively demand higher efficiency requirements, the inquiry develops: what future technologies might further raise the abilities of galvanometer scanners in this developing landscape?

Recognizing Galvanometer Scanners

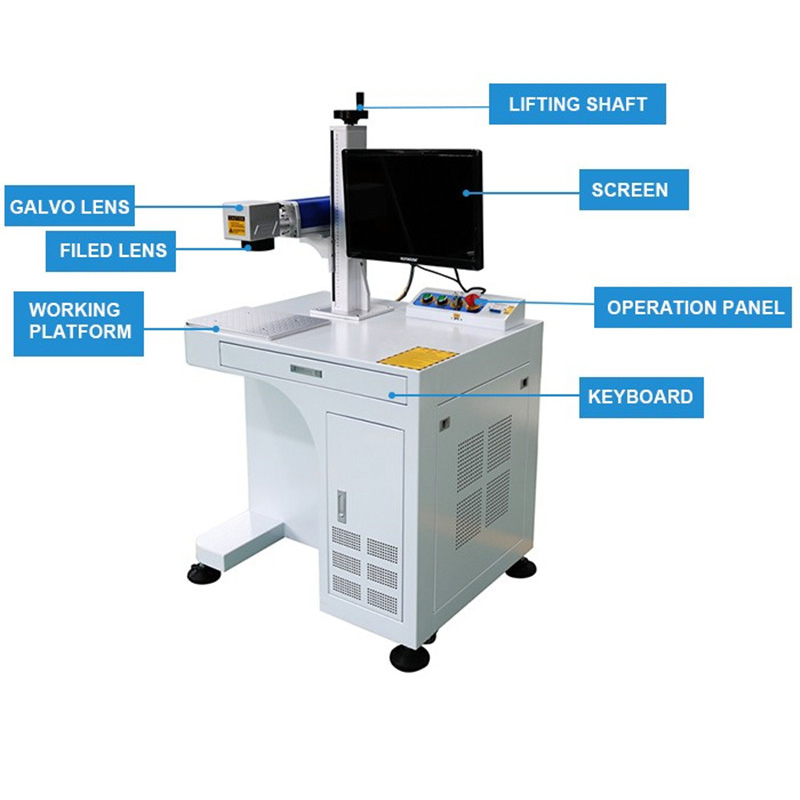

A galvanometer scanner is a sophisticated tool that leverages electro-magnetic concepts to achieve specific angular motion of mirrors or various other reflective surface areas. These scanners operate with the communication of an electric existing and a magnetic field, allowing accurate and rapid placing. This modern technology is important in applications requiring high-speed scanning, such as laser engraving, optical interaction, and medical imaging.

Galvanometer scanners are often identified by their quick action times and high angular resolution, making them suitable for applications that demand quick activities and exact placing. Their integrity and performance make them a vital part in contemporary laser scanning modern technologies, contributing substantially to advancements in numerous areas, consisting of production, healthcare, and telecoms.

Mechanism of Laser Beam Control

The control mechanism counts on closed-loop comments systems that constantly keep an eye on the beam's setting. The signals from optical sensors supply real-time data to the control system, enabling for quick adjustments to keep precision. This is critical in applications where even minor variances can compromise the quality of the check or etching.

In addition, the galvanometer's feedback time is paramount; high-speed motors make it possible for quick activities, making sure that the laser beam of light can quickly map complicated patterns or carry out complex operations. The combination of digital signal handling better improves the responsiveness and precision of the galvanometer scanner. Generally, the device of laser beam control with galvanometer scanners exhibits the combination of innovative engineering and innovation, producing high-performance results in laser scanning applications.

Advantages of Improved Precision

Enhanced accuracy in laser scanning innovations provides considerable advantages across various applications, from commercial production to clinical procedures. The combination of galvanometer scanners allows for highly precise beam of light positioning, which is crucial for jobs calling for careful detail. This improved accuracy ensures that the laser can target details areas with marginal inconsistency, resulting in superior high quality outcomes.

In commercial contexts, accurate laser scanning results in improved product uniformity and lowered material waste. Parts made with high accuracy are much less most likely to call for rework, therefore improving efficiency and reducing operational expenses. In medical applications, the accuracy of laser treatments can considerably influence patient end results. In laser surgery, precise targeting minimizes damages to bordering tissues, leading to quicker healing times and less problems. galvanometer scanner

Additionally, improved precision facilitates innovative applications such as 3D imaging and microfabrication, where even minute inaccuracies can cause considerable errors. By giving repeatable and trusted laser positioning, galvanometer scanners contribute to the total performance and efficiency of laser systems. In summary, the benefits of improved precision not only boost functional efficiency but also raise the standards of top quality and security in different markets.

Applications in Different Industries

The versatility of galvanometer scanners in laser scanning technologies extends throughout multiple markets, each taking advantage of the accuracy they supply. In the medical field, these scanners are essential in applications such as laser surgical procedure and imaging, permitting extremely precise targeting of cells while decreasing damage to bordering locations - galvanometer scanner. Their rapid action and great resolution are check this site out important in generating high-grade results

In the production field, galvanometer scanners enhance processes like laser engraving and cutting. Their capability to quickly guide laser beam of lights onto surface areas makes it possible for reliable manufacturing lines, enhancing rate and precision in developing intricate layouts or elements.

The auto industry also maximizes galvanometer technology for top quality control and examinations (galvanometer scanner). By using high-speed scanning, makers can spot defects in assemblies or materials, ensuring that items satisfy stringent standards

Moreover, in the home entertainment field, galvanometer scanners are used in laser light programs and screens, providing dynamic visual experiences with specific control over laser motions.

Future Patterns in Laser Scanning

Emerging innovations are poised to change the landscape of laser scanning, with galvanometer scanners at the forefront of this transformation. As sectors increasingly require precision and effectiveness, the advancement of galvanometer modern technology will certainly drive significant improvements in laser scanning applications.

Future trends show an expanding assimilation of expert system and artificial intelligence formulas, which will certainly improve information processing capacities and automate decision-making in real-time. This harmony will certainly allow for more sophisticated analysis of checked information, causing boosted accuracy in applications such as 3D modeling and independent navigation.

Furthermore, the miniaturization of elements and anchor the advancement of innovative materials will contribute to lighter, more portable laser scanning systems. This portability will certainly expand the reach of laser scanning innovations into previously unattainable atmospheres, such as remote surface and intricate architectural areas.

The surge of increased fact (AR) and online truth (VIRTUAL REALITY) applications will certainly likewise shape the future of laser scanning. By combining galvanometer scanners with AR and VR, users will certainly gain from immersive experiences that improve visualization and job planning.

Conclusion

In final thought, galvanometer scanners play a crucial role in enhancing laser scanning technologies via their precise control of beam of light instructions and rapid angular changes. The integration of innovative comments systems and optical sensors dramatically boosts functional rate and precision, leading to improved end results in applications such as laser engraving and clinical imaging. As industries increasingly take on these technologies, the recurring advancements in galvanometer scanner designs are expected to more elevate efficiency criteria and broaden application possibilities.

The combination of galvanometer scanners in laser scanning technologies stands for a pivotal advancement in precision engineering. Overall, the device of laser light beam control via galvanometer scanners exhibits the fusion of sophisticated engineering and innovation, producing high-performance outcomes in laser scanning applications.

By supplying dependable and repeatable laser positioning, galvanometer scanners contribute to the general efficiency and effectiveness of laser systems.The convenience of galvanometer scanners in laser scanning modern technologies extends across multiple industries, each profiting from the precision they give.In verdict, galvanometer scanners play a critical duty in enhancing laser scanning innovations via their specific control of beam direction and fast angular adjustments.

Report this page